Sustainability

Sustainability Vision 2030

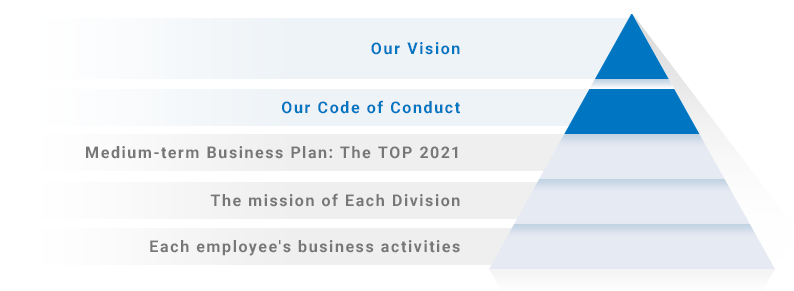

As a member of Resonac Group, our company operates according to the group’s CSR Policy. The CSR Policy "aims for companies to contribute to achieving the SDGs through business operations, and become corporately responsible organizations that satisfy stakeholders by having all employees adhere to the group’s code of conduct". Our company will provide products, technologies and services that contribute to the creation of a society where prosperity and sustainability are harmnized.

Initiatives to Achieve the SDGs (Sustainable Development Goals)

About the SDGs (Sustainable Development Goals)

In September 2015, the United Nations Sustainable Development Summit welcomed heads of state from over 150 member countries, leading to the adoption of a document known as the 2030 Sustainable Development Agenda. This agenda established the Sustainable Development Goals, which are comprised of 17 benchmarks and 169 targets for achievement by 2030.

The SDGs are distinguished in that they set challenges that require resolution through united action by the public and private sectors. We will use its business to contribute to the development of a sustainable society.

Regarding Shiojiri Plant’s Registration as an SDG Partner Company in Nagano Prefecture

Our Shiojiri Plant has been recognized as an SDG Partner Company, taking advantage of Nagano Prefecture’s SDG partner registration system. The program links (visualizes) the SDG benchmarks to corresponding activities, and is expected to further improve our corporate value.

Going forward, the Shiojiri Plant will conduct PR and awareness activities among employees, implement activities to address as many SDGs as possible, and partner with Nagano Prefecture and other registered companies, while simultaneously promoting activities that will make the SDGs more familiar on an individual level.

-

Nagano Prefecture SDG Partner Company Registration Certificate

-

Declaration for Achieving the SDGs (Requirement 1)

-

Specific Initiatives for Achieving the SDGs (Requirement 2)

Safety Initiatives

Across all of our business activities, We works to prevent occupational hazards, accidents, and health-related hazards to employees. We work to create a safe, comfortable work environment, and aim to improve our health and safety standards. In order to ensure that employees can work safely and healthily, we manage the workplace environment and tasks, provide opportunities to learn rules and work methods that keep employees from damaging their health, and perform regular checks to ensure that job activities have not negatively affected employee health. Specifically, we eliminate accidents and hazards through concrete measures and clear objectives. This includes Danger Prediction Activities to eliminate unsafe behavior, Risk Assessment to set up equipment so as to avoid inadvertent injury, Reports on Potentially Dangerous Monir Incidents to prevent recurrence of accidents, Safety Inspections to ensure proper performance of equipment and tools, Keeping Things in Order, Cleaning, and Neatness activities to provide a comfortable workspace and eliminate problem areas, Mutually Cautious Operations to maintain awareness of carelessness, Safety Education to provide everyone with the skills to work safely, and Workplace Inspections and Observations by Outside Experts to monitor workplace health and safety and maintain a comfortable workplace.

Toyama Plant Lifesaving Training

In continuing our safety initiatives, we believe that companies have a social responsibility to protect their employee’s life, health, and families. We aim to be a company that will be trusted and chosen by the local community. Our employees and those of our partner companies are all united as one. We work to improve occupational health and safety standards, and we make these values the highest priority. Believing that health is an important motivator for working, we are driven to create a work environment where people can maximize their abilities.

* Only available in Japanese

Environmental Issues and Responsible Care Initiatives

We considers the local environments of its production bases, and is working to develop a business that is aware of its responsibilities as a handler of chemicals that directly impact on the surrounding area. As such, through dialogue with local stakeholders at our three production bases, we are fostering understanding and trust towards our business activities while simultaneously continuing to provide information by issuing CSR reports on the status of the environmental conservation activities we are driving forwards.

As we increasingly focus our attention on the greater regional environment, our company believes that reducing the environmental impact caused by our business activities and preserving the environment are the crucial management challenges. As such, we are further reducing risks and environmental impact. We are identifying, avoiding, and reducing risks that arise from our business processes, and identifying and reducing environmental impacts that arise across each stage of the life cycle, including product development, raw material purchase, production, shipping, consumption and disposal. We are preventing air and water pollution, saving resources and energy. We are aiming to decrease our environmental impact through such efforts.

In addition, in order to comply with environmental laws, regulations, agreements, and demands from our stakeholders, We have acquired ISO14001 certification, and is creating, maintaining, and operating an environmental management system. Through environmental education and awareness activities with employees at our plants and partner companies, we aim to improve awareness of environmental reforms, clarify specific goals and benchmarks, encourage environmental management activities, and conduct periodic reviews to reflect conditions.

Our common goal is to create harmony with nature and the local region. In order for each employee to take continued proactive initiatives to conserve the environment based on our environmental policy, we have established voluntary standards and are managing and monitoring environmental impact in order to protect nature and conserve the surrounding environment. Our environmental policy is provided to all employees and publicized outside the company.

Yokohama Plant Cleaning Activities

* Only available in Japanese

Quality Assurance Initiatives

In order to gain customer trust for every product and service, and to stably provide safe products, Showa Denko Ceramics Co., Ltd. is working to maintain and improve a system to prevent unsatisfactory products from being made, shipped, or received. In addition to product quality, our quality assurance activities target quality across company operations, including service quality, work quality, and employee quality. We work to provide products and services that will satisfy our customers. As such, we created regulations and standards using the 4 Ms (Man, Machine, Material, and Method). These are fundamental factors for creating quality that will support the safety and peace of mind. We are maintaining our management standards while continuing to provide a quality management system that provides peace of mind across every field of operation.

With regard to products to be purchased by customer, we maintain awareness of customer conditions and changes in their business environment. Across every stage, from product planning, configuration and design to evaluation, production, sales and support, we work to create satisfactory products based on a shared principle that prioritizes the customer’s desires.

In order to ensure the safety of our products and services, we provide support and improvements according to various usage methods. We are working to improve the safety of our ongoing products and services, issuing SDSs (Safety Data Sheets) with legally required information about physicochemical properties, dangers and hazards, and handling chemical substances. In addition, we include a GHS label for required products to ensure safe use, and provide suitable support with cautions and warnings to prevent accidents from misuse or carelessness.

We have obtained ISO9001:2015 certification, an international standard for quality management systems.

![[Quality Assurance System for Customer Satisfaction] Quality Assurance Activities:Deploying Policies・Manager Board・Management Review・Internal Audit,Assuring Fixed Level of Quality (Performance, Etc.):Quality Manual・Product Inspection Points・Product Inspection Method,Reducing Costs though Improved Production Efficiency:Nursing Versatile Workers・Loss Reduction・Improved Yields,Adopting New Technologies:New Product Development,Control for Multiple Functions(Optimization, Simplification):Manuals・Automation,Ensuring Interface Compatibility and Consistency:SAP System,Providing Accurate Information(To Encourage Mutual Understanding):Sales Reports,Protecting Quality of Customers'Poroducts:Customer Support・Product Risk Assessment・Process Abnormality Report,Creating Employee-Friendly Regulations:Measurement of Work Environment・Hazard and Impact Assessment,Managing Use of Environmentally Hazardous Substances:Certification System for Non-Use ofEnvironmentally Hazardous Substances](/common/img/sustainability/img-sustainability-en-02.png)

* Only available in Japanese