Technologies

Technology Introduction

Shiojiri Plant

Our outstanding R&D capabilities and distinguished products

contribute to advancements in various industries.

We offer ceramic products to a wide range of fields including steel, automotive, machining, electronics, and daily living. We can produce ceramic grains with various sizes and shapes suited to the usage applications and demands of our customers.

Crushing and classification technology

With highly efficient crushing and classification technology for crushed materials, we can provide both fine crushing capabilities and high productivity.

Kneading and extrusion technology

We are equipped with extrusion molding technology that can produce high yields of products with desired particle size, and mixing technology that can achieve the uniform composition of multiple types of crushed material.

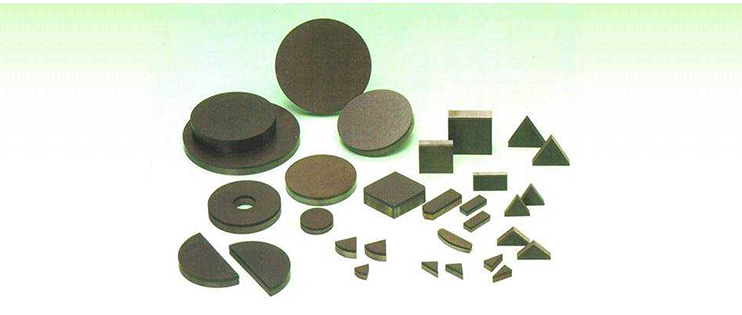

Ultra high pressure and high temperature sintering process

We are equipped with ultra-high pressure and high-temperature sintering technology that can handle production conditions exceeding 5GPa/1,200℃.

Composite sintered body fabrication technology

We are equipped with fine particle mixing technology that achieves highly dispersed mixes of sub-micron particles.

Heat Treatment Technology with High-Temperature

By using various kilns and reaction furnaces capable of performing high-temperature treatments to carry out chemical and physical reactions, we can manufacture a wide range of fillers controlled for crystalline diameter size and particle shape.

Compounding and surface treatment technology

Through surface treatment technology matched for filler composition and various resins, we can provide fillers specially tailored for resin performance.

Toyama Plant

We provide customers with technologically advanced ceramics materials.

We process and produce ceramics materials used in electronic components and advanced industries that are indispensable for electronics with

advanced technology.

We support your life.

Going forward, we will continue to refine our cutting-edge technology to meet the various needs of our customers.

Ultrafine titanium dioxide synthesis technology

We use titanium tetrachloride to produce high purity ultrafine titanium dioxide. This material is used to make multilayer ceramic capacitors, which are mounted on various electronic devices.

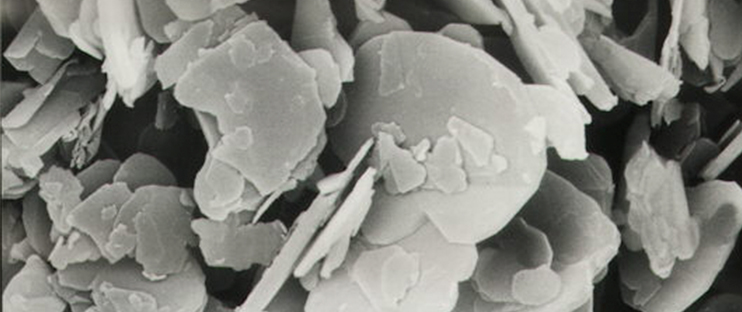

Rare earth processing technology

We crush and fire materials mainly composed of cerium oxide. We can provide variety of abrasive for glass to meet our customer's needs.

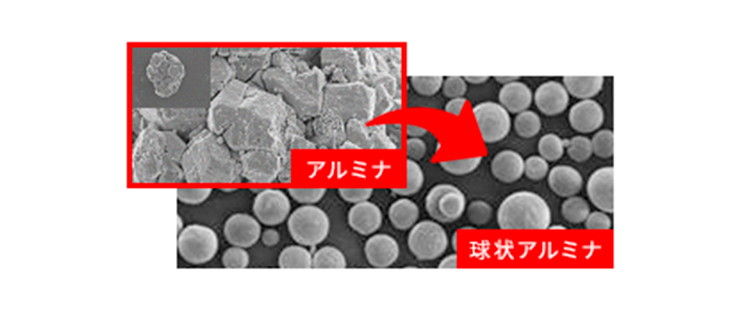

Alumina spheroidizing technology

Alumina is melted in a high-temperature flame and spheroidized with high precision by surface tension. High sphericity and uniform particle size realize highly efficient filler.

Yokohama Plant

We will continue to explore the potential of alumina properties.

In recent years, usage of alumina has been expanding across a range of fields, including not only electronics and cutting-edge industries, but also daily living and other areas that help achieve a more comfortable lifestyle. At our Yokohama Plant, We take advantage of our wealth of experience and pergformance to achieve our customers' requirement.

Heat Treatment Technology with High-Temperature

By using tunnel kilns capable of performing high-temperature treatments to carry out chemical and physical reactions, we can manufacture a wide range of fillers controlled for crystalline diameter size and particle shape.

size reduction technology

Our crushing and classification technology nourished through many years makes it possible to configure the optimal particle size and create fillers with a diverse range of particle diameters and distributions.

Surface Treatment Technology

Through surface treatment technology matched for filler composition and various resins, we can provide fillers with high fillability for resin performance.