Human Rights and Labor Practices

Human Rights

We respect human rights, and create new value through honoring individuality, free thinking, and constructive discussion.

In addition to preventing discrimination by all employees, both inside and outside the company, we actively work to respect human rights, including engaging our supply chain in a move toward resolving the human rights issues that exist in international society, such as racial discrimination, class-based discrimination, child labor, forced labor, and poverty.

We aim to create a climate of new value by our diverse personnel honoring each other’s individuality, being free thinking instead of bound by precedent, and engaging in constructive discussion.

Human Rights Education

The Resonac Group has established “Our Code of Conduct” as fundamental, guiding rules for all employees. Above all, conducting business activities that take human rights into consideration is essential to protecting our colleagues and gaining the trust of business partners, customers, and the local community who join us in creating a better society. Because of this, the “Resonac Group Human Rights Policy” was formulated as a promise to all our stakeholders.

We established an e-learning program for all our employees to study why and how our company must take measures to respect human rights, as well as the “Resonac Group Human Rights Policy” that forms the basis for this, to deepen the understanding of respecting human rights.

Furthermore, in addition to issuing a TOP message every October on the Code of Conduct, including the Human Rights Policy, we promote continuous education so that, by discussing what they can do in their respective workplaces, each employee will embrace human rights as a personal commitment and the policy will take root as company culture.

Measures for 5 S’s Activities

With a goal of creating a comfortable and safe working environment, each workplace is engaging in 5 S’s activities: Seiri (organizing), Seiton (tidying up), Seiso (cleaning), Seiketsu (cleanliness), and Shitsuke (training).

In addition to plant management taking the initiative to implement routine patrols, each workplace is led by a chosen committee member who clarifies goals and objectives to promote voluntary initiatives.

Improvement Proposals and Near Misses

Improvement proposals are activities for collecting and implementing suggestions from the site and employees to increase operational efficiency and enhance quality. Near misses are reports that identify “danger” before an accident or problem occurs, serving as a warning or indicator to guard against unforeseen disasters. Both improve the organization’s safety and quality and are important techniques in strengthening risk management. Outstanding initiatives are also awarded prize money through awards such as the Factory Manager's Award and the Most Proposals of the Year Award.

Consultations with the Labor Union

Our company ranks consultations with the labor union as an important partnership, and our goal is to improve the ease of working and satisfaction level of our employees through discussions rooted in mutual respect and trust. In particular, we identify problems in cooperation with the union to promote policies that reflect employees’ remarks and implement proposed solutions to improve engagement scores. Specifically, we concentrate on measures such as work style reform, fulfilling employee benefits, and improvements to the working environment, and we’re working together to realize an environment where employees are highly motivated to work.

Through these collaborative measures, the goal is to achieve both the individual growth of employees and the sustainable development of the organization.

Furthermore, twice a year, business overview labor/management meetings are held to discuss how business activities and the treatment of union members should be to realize the growth of both the company and individuals.

The company CEO and executives attend, explaining such matters as management policies, action plans, related business measures, and the direction of corporate activity. Union officers from the head office and branches attend, and in addition to giving their opinions based on workplace conditions, they make recommendations regarding member treatment and other necessary measures.

In 2024, topics discussed included sharing the results and goals of business efficiency and the digital transformation promotion, the importance of direct communication with employees to improve engagement, and improving the workplace’s appeal through better recruiting sessions and PR activities.

Safety Measures

Plant Safety Patrols

To thoroughly identify on-site hazard sources from various viewpoints, patrols from a wide variety of perspectives are conducted regularly, such as manager patrols, joint labor-management patrols, theme-based interim patrols, and patrols calling in outside consultants, to prevent disasters. Along with reporting things noticed on patrols to the person in charge and indicating the needed improvements, they’re also uploaded to a database and the information is widely shared, providing each workplace with an opportunity for review and reflection.

Safety and Health Education

Doing safety activities that incorporate a SCP (Safety Communication Program), we undertake joint labor-management safety patrols on Safety Day and have the mutual “Thanks for the Warning” tour with the goal of realizing a mutually developmental safety culture. All employees take part and it’s composed of members who have different knowledge and experiences. By visiting each other’s workplaces, they compare the actual work with the work guidelines and share good points they noticed with each other for planned improvements. Conversing with people from other departments they’ve usually never talked with before, safety activities provide an opening for revitalizing communication and engagement. We also support the Ministry of Health, Labor and Welfare-sponsored “Stop Heatstroke!” cool campaign where WBGT meters were installed in each workplace to make the risk of heatstroke more visible, and conduct heatstroke prevention activities such as safety education and health management check sheets. We contributed to the safety culture in our plants by drawing attention to the recent rise in accidents to increase awareness, and by forklift safety education where the company’s veteran drivers and forklift makers conducted safe driving training on a special course for practical skills.

Safety Review

Receiving applications for new projects, expansions, modifications, and demolition work, as well as the new operations or operation changes that accompany them, the people concerned gather at the design stage or before the trial run and review the safeness of the equipment and operations.

Furthermore, we rate the effect these activities have on quality and the environment, making our tasks clear to take the appropriate response and maintain a safe workplace environment.

Conducting the “Thanks for the Warning” tour

To realize a mutually empowering safety culture that can save not only your own life but those of your coworkers as well, the plants engage in mutual “Thanks for the Warning” tours. Splitting into teams composed of everyone from plant managers down to new employees, regardless of experience or job title, they meet with several others they may not ordinarily have spoken to, visit each other’s workplaces, share good safety-related points they noticed, and implement improvements. Safety activities contribute to revitalizing communication and engagement.

Chemical Management

These days, many regulations pertaining to chemical management are shifting to strongly requiring autonomous management by business operators. To comply with this, we share information and collaborate closely through the chemical management committee meetings our company and the plants hold quarterly, interpret the requirements from revisions to national or international regulations and enact them in each plant in addition to insisting workers wear protective gear to protect their health from harm when using chemical substances as well as moving forward with centralized management of safety measures so that nothing is overlooked.

Recreation

You might know the name and face of other coworkers working at the same plant but never talk with them if their workplace is far away or they’re on a different shift, so there are few opportunities to get to know fellow employees. We plan various recreation events that not only create smooth communication and an identity, but also help workers’ families understand the company’s measures and allow people to have fun across generational and organizational lines. We’re proceeding with activities that everyone can enjoy while also contributing to promoting good health, with sports like soft volleyball and mallet golf, or strawberry-picking walking tours. Furthermore, we’ve also conducted joint photo contests or a walking campaign where participants from all three plants competed in their number of steps, which were well-received as an opportunity to foster a sense of unity at Resonac Ceramics.

Harassment Prevention

We aim to create a workplace free of harassment and conduct training and awareness activities to eradicate all forms of harassment, including sexual, power, and maternity harassment.

We conduct e-learning for all employees, and in addition to teaching fundamental knowledge about harassment, the importance of creating a workplace free of harassment, and things to be careful of so you don’t harass anyone, we conduct harassment prevention training for management so they understand the importance of “harassment prevention” and learn what they should be thinking about at the executive level and what countermeasures they need to take.

Furthermore, we have established consultation desks at each site with a system that ensures victims can consult with confidence. The content of their consultation is strictly confidential; by ensuring a rapid and appropriate response, we gain the trust of our employees.

Promoting Employment of the Disabled and Elderly

Our company values diversity and inclusion and takes various measures to meet our social responsibility to realize an inclusive society.

Our employment of people with disabilities not only complies with the legal employment rate, but through establishing appropriate workplace accommodations and support systems tailored to their needs, we provide an environment where people with disabilities can sustainably demonstrate their abilities.

Furthermore, we have high hopes that the elderly can contribute to the development of the business by using the expertise they cultivated over long years, and we’ve established a re-employment system for people going back to work after retiring at 60, flexible working styles, and adjustments for an age-friendly workplace so elderly employees can put their knowledge and experience to good use and continue working with a sense of security.

Health Care/Mental Health Care

Our purpose is to “change society through the power of chemistry” and we aim to contribute to a sustainable society, so we promote health and productivity management that emphasizes the health of employees and their families. We hold online health seminars, and are deploying cross-sectional health promotion activities in our three plants in Shiojiri, Toyama, and Yokohama. We conduct walking events as a countermeasure to the health issues of high cholesterol and high blood pressure. And the Shiojiri Plant is collaborating with Matsumoto University (in Matsumoto, Nagano) to provide support to continue exercising using activity trackers. An increasing number of people are taking part in the events, leading to an increase in employees’ health consciousness. We aim to increase corporate value to the fullest through health and productivity management, as well as to create an environment where everyone can thrive healthily and build a rich future.

Furthermore, stress and mental health issues for workers are trending upward with changes in the social landscape. At our company, we’re taking various measures to support the mental health of our employees, so that they’ll feel secure as they work. Specifically, in addition to health counseling and workplace environment improvements suggested by medical staff, group training related to stress coping strategies and a consultation desk, and line care training for managers, we’re introducing EAP (Employee Assistance Program) in cooperation with external organizations and return to work support programs. We strive for interprofessional collaboration and to create a workplace environment for working securely going forward.

Labor Practices

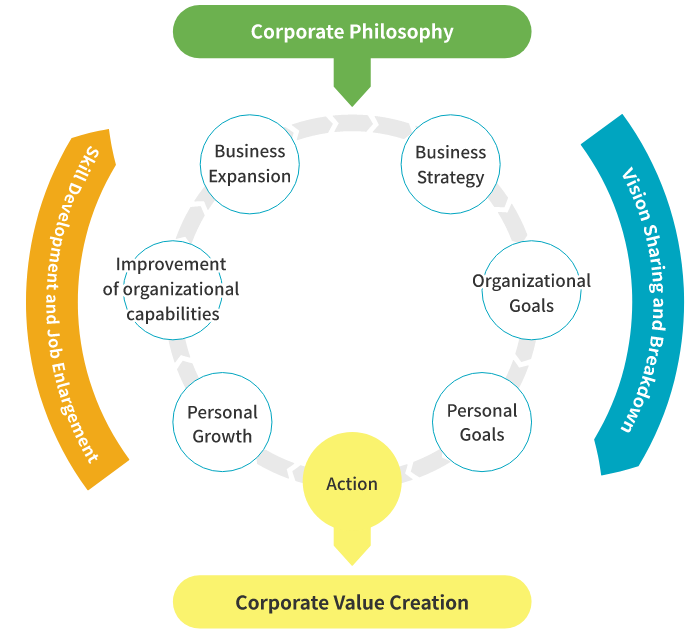

We promote increasing the work motivation of every single employee and creating a workplace where it’s easy for anyone to work.

We make our human resource development policy clear to develop our employees’ skills and provide a workplace environment with meaningful work.

We take thorough measures to establish a safety- and health-conscious workplace environment so that employees feel secure while working.

Human Resource Development Measures

At our company, after clarifying our ideal talent profile, we continuously update our educational system to create a corporate culture that encourages skill development.

Furthermore, in new employee training, promotion training, mid-level leader training, etc. we envision an employee’s career path and conduct rank-specific training to give them more than the desired skills at each grade. After each training session, we review the training content based on participant surveys to identify areas for improvement and to understand changes in needs due to changes in the internal and external environments.

Ample rank-specific training to give the knowledge necessary for the job

Ample selected training to nurture the employees who are our future

Financial assistance for distance learning courses and obtaining certifications

Personnel exchange activities outside the plant or office framework

Adjustment of personnel system and transparent operations (performance appraisal system, promotion system, wage system, etc.)

Response to Emergency Situations

Basic Life-saving Course

We invite external lecturers to teach appropriate treatment methods for injured or ill people and emergency procedures based on actual cases, and also provide training using AEDs (automated external defibrillators) installed in the plants.

Emergency Procedures Drill

We conduct initial response training to minimize damage by assuming possible maintenance or environmental abnormalities that may occur during production activities at each plant and department. In particular, we conduct thorough training to deal with drainage abnormalities and leaks related to water quality and air quality around the factory, which are of concern. In addition to equipment countermeasures such as automatic shut-off valves and alarm devices, we also conduct training that includes manually placing sandbags and visually checking wind direction and speed.

Fire Extinguishing Equipment Inspection

The fire extinguishers, fire hydrants, and fire alarms installed in the plants are inspected twice a year so that the fire extinguishing equipment will operate properly in the event a fire occurs.

The inspections are done by a professional with specialized knowledge, who inspects them externally for damage and confirms they’re in proper working order. Furthermore, we report the inspection results to the fire department every three years.

Evacuation Drill (Preparations for Natural Disasters)

Anticipating the typical geological risks and the natural disasters that may occur, each plant conducts an evacuation drill for the entire plant staff, including on-site partner companies and affiliated companies, every November 5, which is Tsunami Disaster Prevention Day. Beginning with a broadcast throughout the premises notifying us that a disaster has occurred, the drill is conducted with great emphasis on how quickly we can evacuate to the designated location with orders given over walkie-talkies or cell phones and cooperation within departments and on checking that everyone is safe. Furthermore, in consideration of cases where people are forced to stay there, such as those stranded by the disaster or from the Business Continuity Planning (BCP) angle, we prepare not only provisions but everything necessary for life during evacuation: generators, lights, heaters, portable toilets, blankets, etc. And thanks to CSR activities at a beverage manufacturer, the multiple disaster relief vending machines set up on-site will provide beverages free of charge during a disaster.

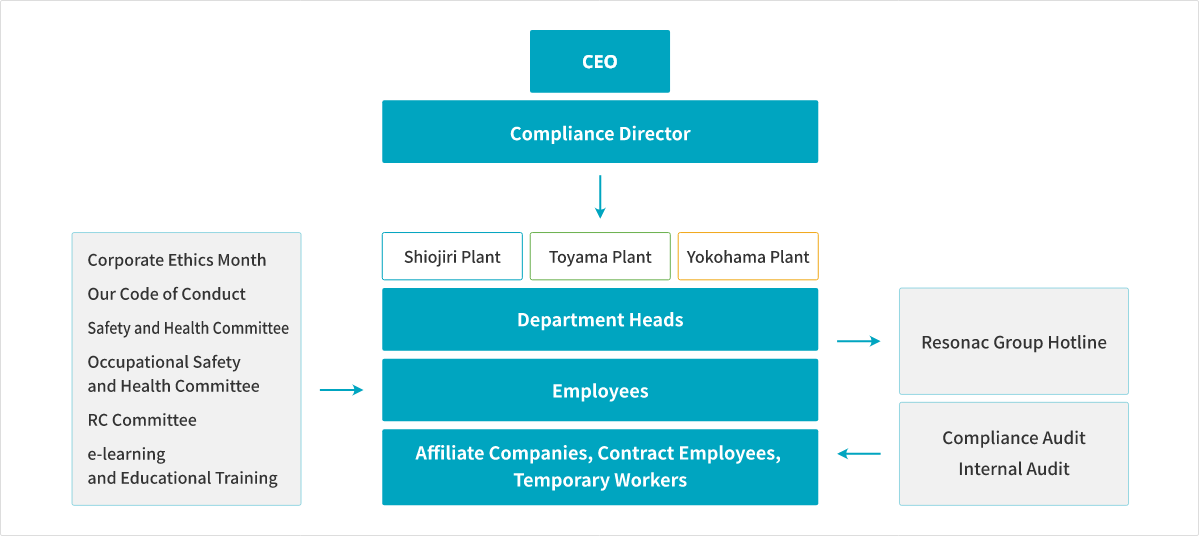

Compliance System

Improvement Activities

Shi-ZUKU Activity (Shiojiri Plant)

We’re promoting an activity dubbed Shi-ZUKU, which is a combination of “Shi” from Shiojiri and “ZUKU,” a word in the Nagano Prefecture dialect that means “spirit and determination.”

To achieve plant targets, all employees share the direction and objectives, with each section and group choosing a theme and collaborating on activities. Briefing sessions are held twice a year, and the opinions and advice gained there are added to the results unveiled at the final presentation.

Briefing Sessions: February 27 and 29, 2024; July 16 and 30, 2024

Presentation: October 25, 2024

Kitokito Activity (Toyama Plant)

The Kitokito activity aims to have zero disasters, accidents, or defects and raise productivity by eliminating losses and waste, and it’s a challenge new employees and veterans alike pursue the whole year.

Improving things little by little with the theme of “it’d be great if we took this measure” in day-to-day operations, the results are then announced and commended. We consider this activity a place for human resource development, and by tackling these themes we can learn specialized knowledge, problem identification, and problem solving.

OASIS Activity (Yokohama Plant)

The 2019 measures in Yokohama Plant’s OASIS activity were lauded, and we received the “Excellence Award” at the Diversity CEO Awards. Teams are organized regardless of age or gender in each workplace, and safety awareness is raised, the plant environment is tidied up, and communication is revitalized through site beautification, KY training, and round-table discussions. By continuing to participate in OASIS activities, we will aim to increase the motivation of each employee and promote independent activities.

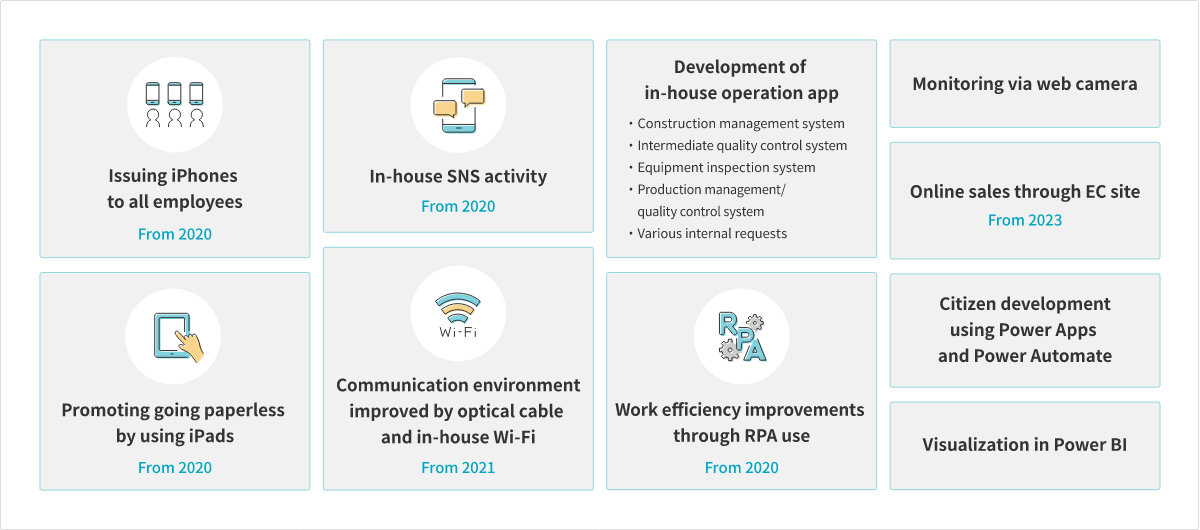

Promoting DIDX

Resonac Ceramics is a digital transformation pioneer even for the Resonac Group, and in 2021 we took the opportunity to begin ongoing revolutionary measures.

Along with forming a DIDX department in the first year, we began by issuing smartphones to all employees. Adopting in-house SNS, we succeeded in revitalizing speedy information transmission and communication. In addition, the use of tablet devices and development of many original apps improved business efficiency, promoted going paperless, and harmonized the business, and we’re presently working toward further improvements.

We will not only support system integration and improving digital skills, but we’ll adopt new IT tools like AI and digital twins, expand the infrastructure environment further, and continue driving the Resonac Group’s digital transformation.

Safety Measure Project

Learning lessons from a disaster that occurred in 2019, we assembled a project team with a goal of advancing the safety measures of the plants’ equipment and technical training for engineers as part of measures to prevent a recurrence. Aiming for a leader-centered structure capable of rapidly and smoothly devising plans and proposals and performing progress management, we launched the “Safety Measures and Production Technology Related Project,” and are striving to establish a safe and secure operational base.

Furthermore, pointing and calling is an effective method for disaster prevention that engages all five senses to prevent human error. To re-establish this activity, we posted custom signage urging its use at crosswalks, control equipment, and entrances and exits across the site. Furthermore, veteran employees are conducting awareness training across all workplaces to ensure the thorough use of pointing and calling, incorporating their past experiences.

BCP (Business Continuity Plan) Measures

In preparation for emergencies such as when a natural disaster strikes, we’re taking measures and creating structures so that the business keeps going as part of our corporate social responsibility. Given the heavy rains, heavy snow, flooding, and so on from extreme weather in the last few years and the frequent occurrence of unprecedented disasters that would be a major blow to the company’s production activities, we’re doing damage estimation and regular re-examinations. We’re taking deliberate equipment measures and reviewing our procedure manuals. And with disaster control headquarters at the center, we conduct joint training in information gathering and transmission over satellite phones and transceivers between plants supposing an emergency, improving the effectiveness of countermeasures and uncovering new issues.