Corporate Governance and Fair Business Practices

Corporate Governance

Comply with all laws and regulations and act with a high sense of ethics.

Understand and comply with the procedures of, or any changes in, the laws, agreements, and social rules and regulations related to the job responsibilities.

Comply with both national and international laws and regulations, and conduct business in keeping with the Universal Declaration of Human Rights and various United Nations conventions.

Even where no rules have been established, take care to speak and act honestly and conduct business as a member of society who has the trust of our stakeholders.

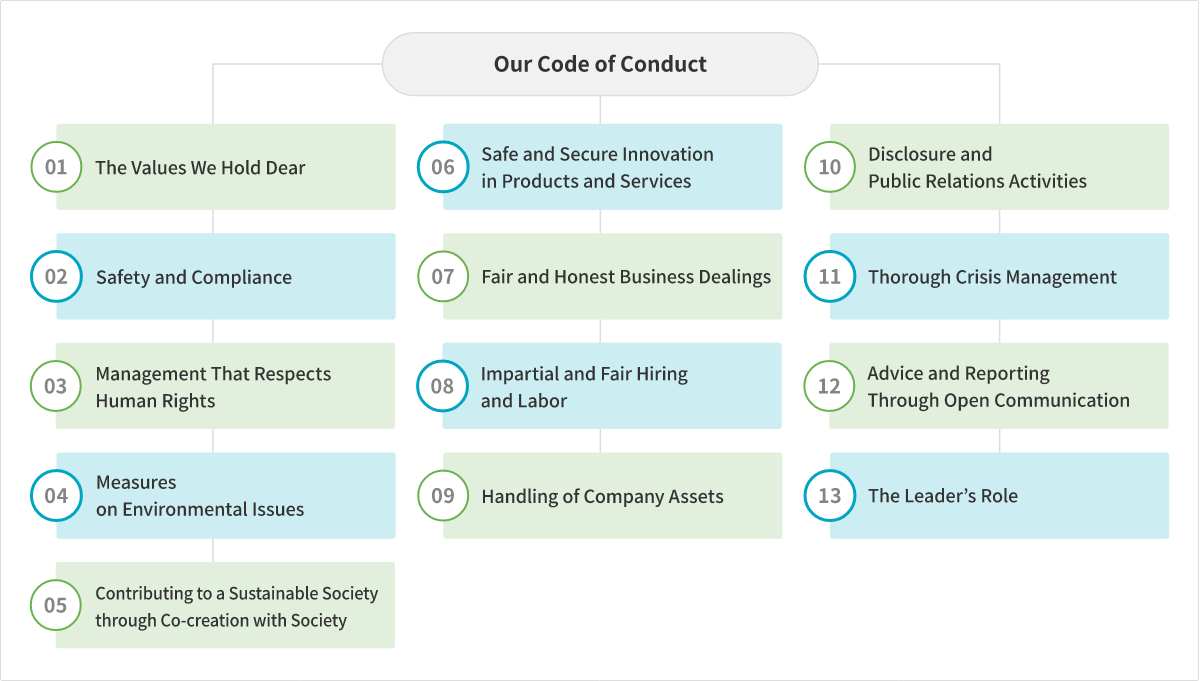

Our Code of Conduct/Compliance

The Resonac Group’s thoughts on sustainability are “to contribute to solving the SDGs issues through our business activities, and to aim for a corporate social responsibility that will satisfy all our stakeholders through the actions of all our company employees based on our code of conduct.”

In accordance with the nine points in our Code of Conduct, we hold discussions in each department where employees identify the actions they must take toward stakeholders after considering what their responsibilities should be.

As a member of the Resonac Group, we will fulfill our duty and contribute to the sustainable development of the international society.

Board of Directors

The Board of Directors decides the fundamental policies of the company and, following deliberation, makes decisions on matters required by the Companies Act, the articles of incorporation, and important business execution matters. This process aims to expedite and revitalize management’s decision-making functions. We systematically conduct four Board of Directors meetings, one Annual General Meeting of Shareholders, and Auditor Audits per year.

Audit by Corporate Auditors

In an audit conducted by our Corporate Auditors, they first confirm the status of duty execution and important approval documents, and then conduct on-site confirmation of business operations and financial status.

Furthermore, the Resonac Group’s auditors conduct a yearly audit, and through their plant overview, production overview, progress on technology and development issues, and on-site physical inspections, we receive recommendations, advice, and guidance on ensuring the soundness of our business.

Auditor by Corporate Auditors: conducted in February 2024

Company-wide Internal Control Audit: conducted in July to September 2024

Compliance Assessment

To confirm proper on-site management and operational status complying with laws and regulations, we conduct the evaluations based on a list of several hundred questions from legal provisions on the environment, safety, chemical management, and facility maintenance.

This measure not only allows us to check our compliance status, but to take planned measures toward laws and regulations that will possibly be enacted and maintain related education, organizational structure, and company regulations, as well as serving an important role as a platform for awareness.

Regulations related to chemical substances and safety measure standards for occupational safety have become stricter and the responsibility placed on companies has grown in recent years, but we promote unfailing compliance with the law through the use of this list.

Internal Audit/Audit by Head Office

Since our founding in 2015, we have been conducting internal audits based on common themes at our three plants, with the aim of improving the skills of our auditors and learning about the products and operations of other plants so that we can apply what we learn to our own workplaces. We are promoting activities through information sharing and synergy effects.

The audit office first discusses the challenges and issues of each plant and selects audit themes accordingly. Conducting the audit from the same perspective by multiple auditors is utilized as an opportunity to discover unique initiatives, insights, and new challenges. Unlike external audits by a third-party organization, appointed auditors audits departments outside their specialty from a broad perspective. This not only deepens understanding of quality, environmental, safety, and health efforts but also helps revitalize communication through mutual understanding between departments. Furthermore, we provide more opportunities for learning and exchange by annually rotating the eligible departments and auditors.

Furthermore, auditors from Resonac Head Office visit the site to conduct RC audits with aim of grasping and evaluating the initiatives, structure, and operational status of environmental safety activities, and promoting continuous improvement.

Quality Risk Assessment (QRIC)

A systematic approach for ensuring the quality of products and services, QRIC (Quality Risk Identification and Control) involves conducting an audit once a year as a method of identifying and controlling quality risks (raw materials, production processes, facilities, human factors, compliance). The main steps are risk identification (identifying potential risk factors), risk assessment (analysis of degree of influence and probability of occurrence), risk control (implementing avoidance, mitigation, relocation plan), and risk oversight (monitoring after implementation). Through this approach, quality issues can be uncovered early on and the appropriate steps taken, making it the key to keeping risks as low as possible and improving quality.

Currently, the three factories are in the preparation stage for the above diagnosis, but they will implement and improve the system from this year to next year, and are working towards establishing QRIC at all three factories by 2027.

Fair Business Practices

Engage in trade based on fair and free competition.

Comply with the Antimonopoly Act and engage in fair trade.

Comply with each country’s competition laws and engage in fair trade

Do not take part in any cartels. Furthermore, take no actions that might be suspected as such.

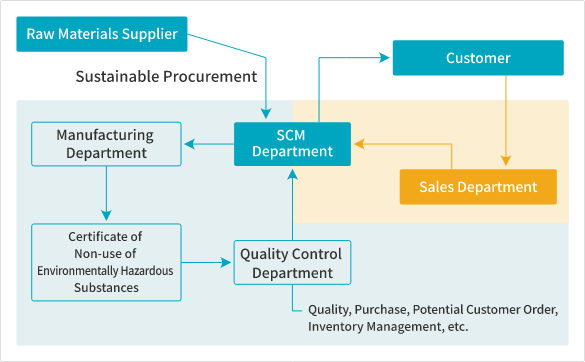

Sustainable Procurement

The “Resonac Group Sustainable Procurement Guidelines” are shared with all our partners through discussions, and in addition to further strengthening the relationship of trust, sustainable procurement is adhered to in our collaborations with a goal of improving our respective corporate values.

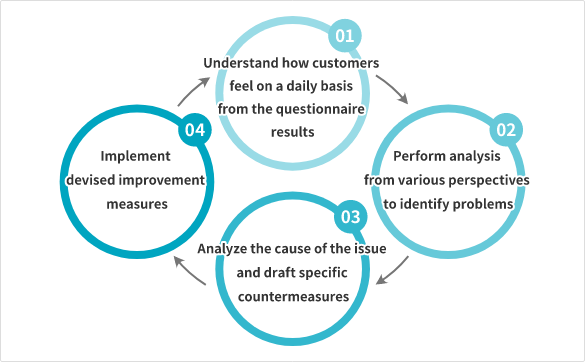

Customer Satisfaction Survey (CS Survey)

This survey is conducted to gauge customer satisfaction and expectations. Collecting feedback from customers, we rate the quality of products and services. The information we receive helps identify points to improve upon, and it serves to improve product quality. And understanding the customers’ needs, we improve our products and services in response, increasing the level of customer satisfaction.

Supplier Assessment

We deliberately and continuously take measures to reassess the track records of suppliers of the main raw materials, packaging materials, logistics contractors, onsite contractors, machine manufacturing, maintenance, construction contractors, etc. in order to guarantee stable procurement from our suppliers.

The evaluation methods are carried out in cooperation with departments concerned by one or more of the following methods, on-site surveys, quality audits, RC audits, BCP audits, CSR procurement, and self-diagnosis.

Consumer Affairs

Collaborate with our business partners to reliably provide products that meet customers’ expectations.

Display products and services clearly and accurately in pamphlets and catalogs.

Give customers the correct facts when recommending or explaining our company’s products.

When selecting suppliers, have an open-door policy and compare them impartially before deciding.

When conducting business with developing countries, take care that ongoing transactions are at fair value so as not to impede their financial independence.

Management System Certifications

Our company has received the International Standards of ISO 9001, ISO 4001, and ISO 45001, and is efficiently conducting manufacturing activities in our plants in compliance with the prescribed frameworks.

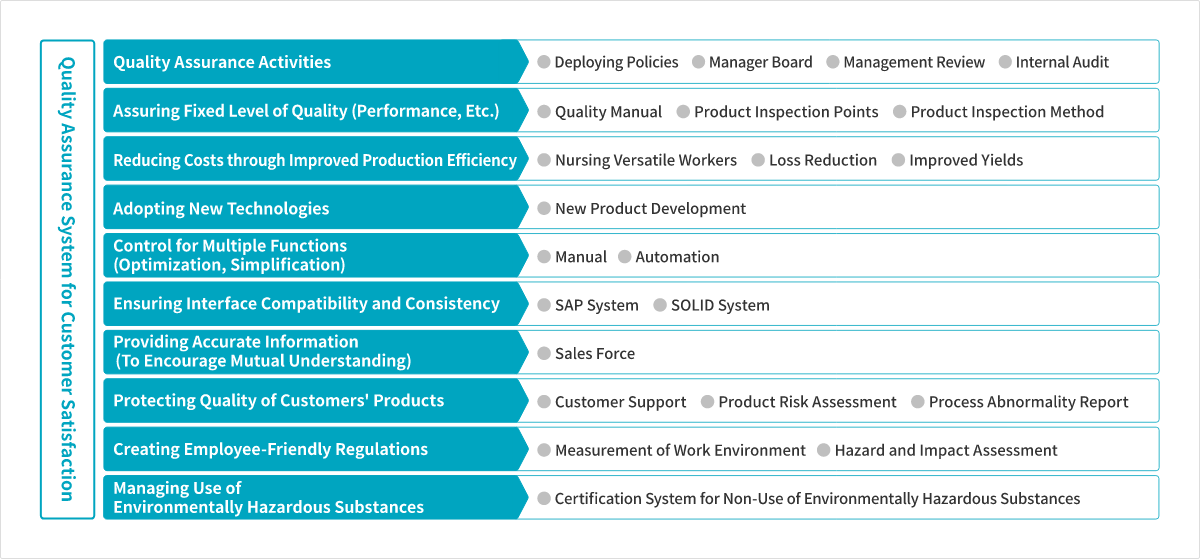

Quality Assurance System

Our company is continuously making improvements to provide our customers with products and services considered practical and safe, products meeting all laws and regulatory requirements, and products that will satisfy our customers.