1

Our glass polishing abrasives are used when polishing display panels, camera lenses, rear panels, and similar components.

Resonac Ceramics products are being used in a wide variety of places as both materials and parts. Although you may not have seen them with your own eyes, these products play a very important role. Our products are incorporated into many household and industrial items to build the foundation for societal development and greater convenience in everyone’s daily lives. These products truly play a vital role, performing significant tasks that remain unseen, “working behind the scenes to support society.”

CASE01

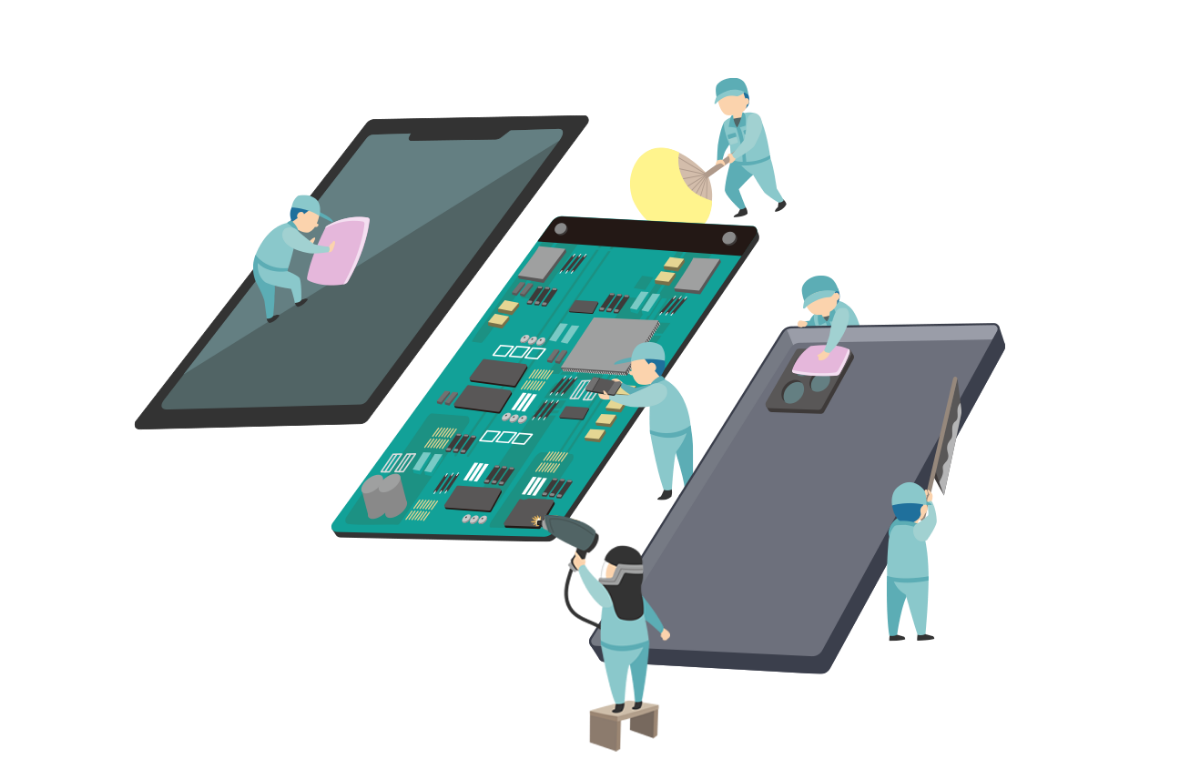

In smartphone manufacturing, our products play an indispensable role—from exterior components such as displays and frames to internal circuit boards and camera lenses—making them essential to the latest technologies.

Click on a number to view the product description!

CASE02

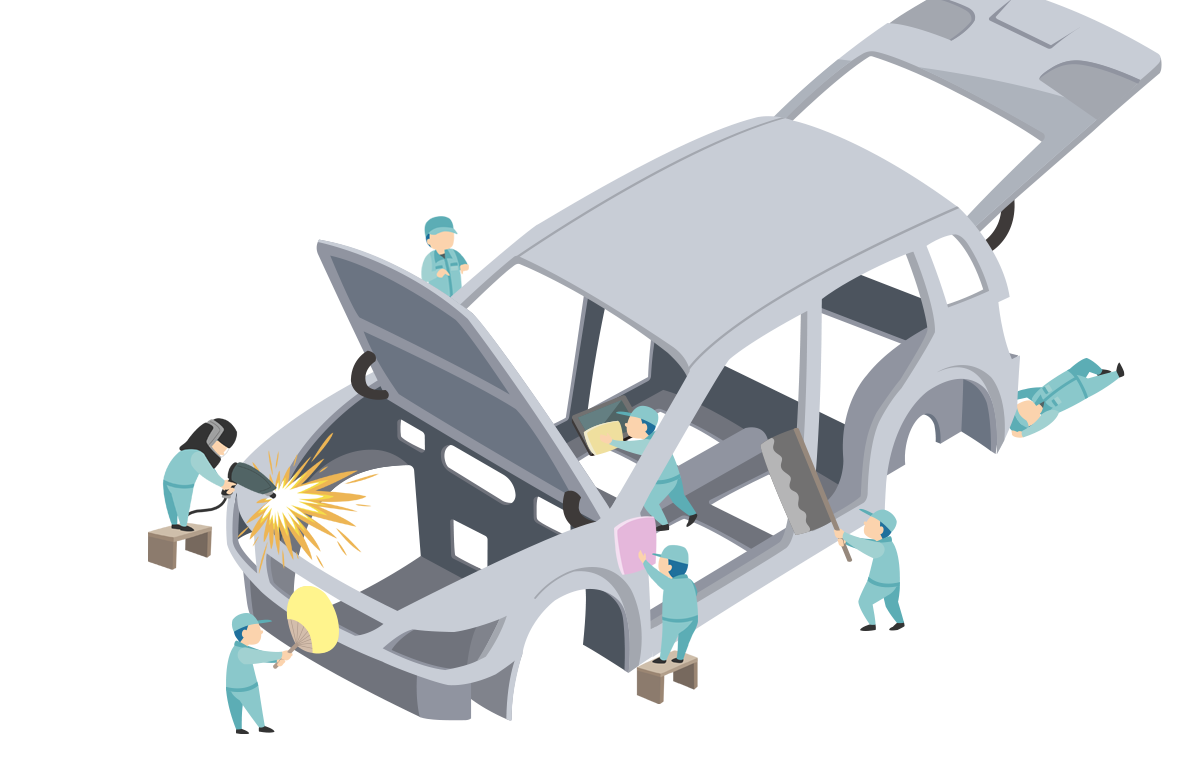

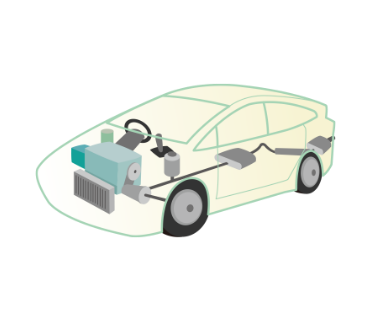

In the automotive manufacturing process, our products are being utilized in many different areas, including exterior parts like the body, powertrain components like the engine, chassis parts like the brakes, and communication and electronic devices such as safety systems, engine control units, and other safety equipment.

Click on a number to view the product description!

MORECASES

Morundum, White Morundum, Single Morundum, Pink Morundum, Sinter Morundum,

Abrasives

Factory Grinding Wheels

Used for Cutting and Polishing Iron Products

Abrasive materials are mainly processed by grinding wheel manufacturers into industrial grinding wheels, which are used for cutting and polishing metals and other surfaces. With proprietary technology cultivated over many years, our company consistently produces high-performance, high-quality products. Industrial grinding wheels are indispensable across a wide range of fields—including automotive, aerospace, machinery, tools, electronics, and construction—where they play a vital role in manufacturing superior products.

SBN K-TIP

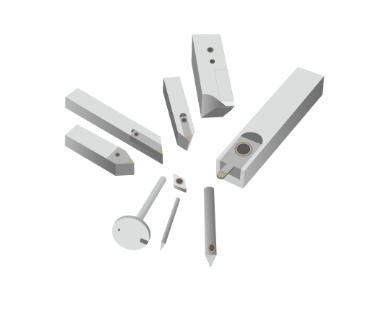

Cutting Tool Material

Cutting Tool (CBN)

Used for Machining Iron-Based Materials Like Automotive Parts

Our cutting tool materials are used for the cutting edges of grinding and machining tools for iron-based materials, primarily in the automotive industry. With hardness and thermal conductivity second only to diamond—and superior high-temperature stability than diamond—they deliver stable cutting performance even under harsh conditions. By enabling higher cutting speeds, they contribute to savings in both fuel and electricity, as well as greater efficiency in the manufacturing process.

SHOROX

Abrasives for Glass

Used in the Process of Polishing Surfaces to a Smooth Finish

LCD Panels, Camera Lenses, Glass Hard Disk Substrates, etc.

By eliminating microscopic scratches and surface irregularities and polishing the material to a smooth, high-gloss finish, we minimize light reflection and scattering. This significantly improves light transmission, resulting in higher quality and functionality for the final product. Our high-quality abrasives for glass polishing are essential components in the manufacturing process of products that demand this extremely high level of transparency and uniformity.

Shomullite, Bubble Morundum, White Morundum, Shofiller, Shozirconia, Shospinel

Electro-fused Refractory Materials

Kiln Slabs/Firing Setters

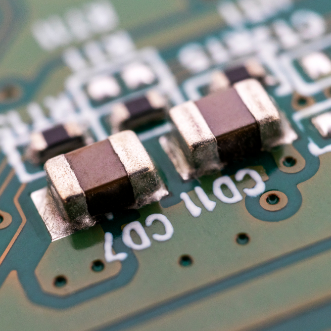

Electronic Components

(Capacitors, Ferrites, Thermistors, etc.)

This material is used as a raw material for kiln slabs (in kilns for cement, ceramics, bricks, etc.) and firing setters (shelf plates used to hold products like electronic components and glass during firing). This is due to its high melting point and superior wear and corrosion resistance. By maintaining its performance during prolonged exposure to high heat and ensuring thermal uniformity, it helps create a stable firing environment crucial for producing high-quality products.

Roundish Alumina, Alunabeads, SHOBN

Heat Dissipating Material

Heat Dissipating Materials for Electronic Devices

PCs, Smartphones, EVs (Electric Vehicles), Air conditioners, Televisions, Refrigerators, etc.

Every product that uses electricity generates heat during operation. Heat dissipating materials are essential for dissipating this heat, which in turn stabilizes equipment performance and prevents degradation. Furthermore, achieving high heat dissipation contributes significantly to the miniaturization of devices. Our products are recognized for their high and stable quality, and as a result, they have been widely adopted for many years in applications ranging from consumer goods to industrial products.

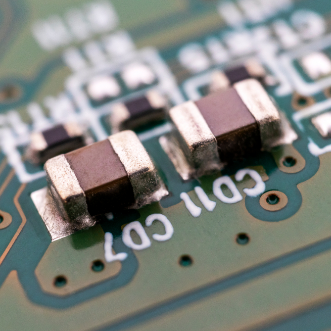

Super-Titania

Materials for Electronic Devices

MLCC: Essential Electronic Components for Semiconductor Devices

PCs, Smartphones, EVs, AI, Robotics, IoT, etc.

Our materials serve as a primary raw material for MLCCs (Multi-Layer Ceramic Capacitors), essential electronic components required to ensure the stable operation of semiconductor devices in everything from cutting-edge fields like AI, IoT, and Automotive applications to everyday devices such as PCs and smartphones. Our advanced technology for producing ultra-fine and high-purity particles will continue to support the evolution of various industries by contributing to the miniaturization of devices and the expansion of these global markets.

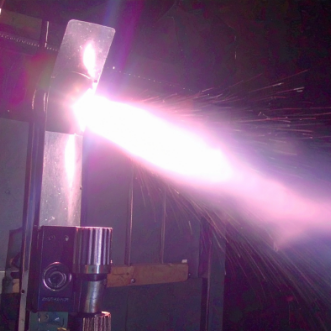

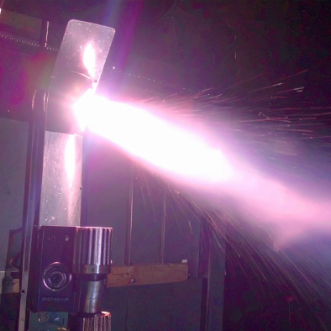

SHOCOAT™

Thermal Spraying Material

Plasma Spraying

Internal Components of an Aircraft

These are the materials used for “Plasma Spraying.” Plasma spraying is a technique that coats the surfaces of components in various machines and vehicles to strengthen them and enhance durability. This technique is applied to critical parts such as turbine blades (used in aircraft and power generation), injection nozzles (part of engines), shafts, and bearings (rotating mechanical parts), etc. By applying this coating, machinery can operate more safely and efficiently.

1

Our glass polishing abrasives are used when polishing display panels, camera lenses, rear panels, and similar components.

Where You Can Find

2

Our heat dissipating materials are used to dissipate heat generated during device use and maintain proper temperature control. This improves the operational stability of high-performance devices and prevents damage.

Where You Can Find

3

Titanium dioxide is used as a primary raw material for MLCCs (Multilayer Ceramic Capacitors), which are indispensable for stable electronic circuit operation, providing voltage stabilization, noise reduction, and more.

Where You Can Find

4

Thermal spraying materials are used when plasma spraying is applied to internal circuit boards and metal components to enhance durability and improve thermal conductivity.

Where You Can Find

5

For cutting and polishing iron-based materials in frames and internal structures, grinding wheels made with abrasives are used, as well as cutting tool materials applied to the cutting edges of grinding and cutting tools.

Where You Can Find

1

Titanium dioxide is used as a primary raw material for MLCCs (Multilayer Ceramic Capacitors), which play a role in supporting the stable operation of electronic devices. These devices include ECUs that control the operation of engines and brakes, as well as autonomous driving and navigation systems.

Where You Can Find

2

Thermal spraying materials are used when plasma spraying is applied to the surfaces of engine components, exhaust systems, and brakes to improve their performance and extend their service life.

Where You Can Find

3

Abrasive materials are used in grinding wheels and as the cutting edges of grinding and cutting tools to cut and polish iron-based materials like engine components and body panels.

Where You Can Find

4

Electro-fused refractory materials are used in exhaust systems and brake systems that need to withstand high friction.

Where You Can Find

5

Glass polishing abrasives are used to polish the LCD panels of car navigation systems.

Where You Can Find

6

Heat dissipating materials are used in DCDC converters, OBC (on-board chargers), and around the battery, all of which generate heat.

Where You Can Find